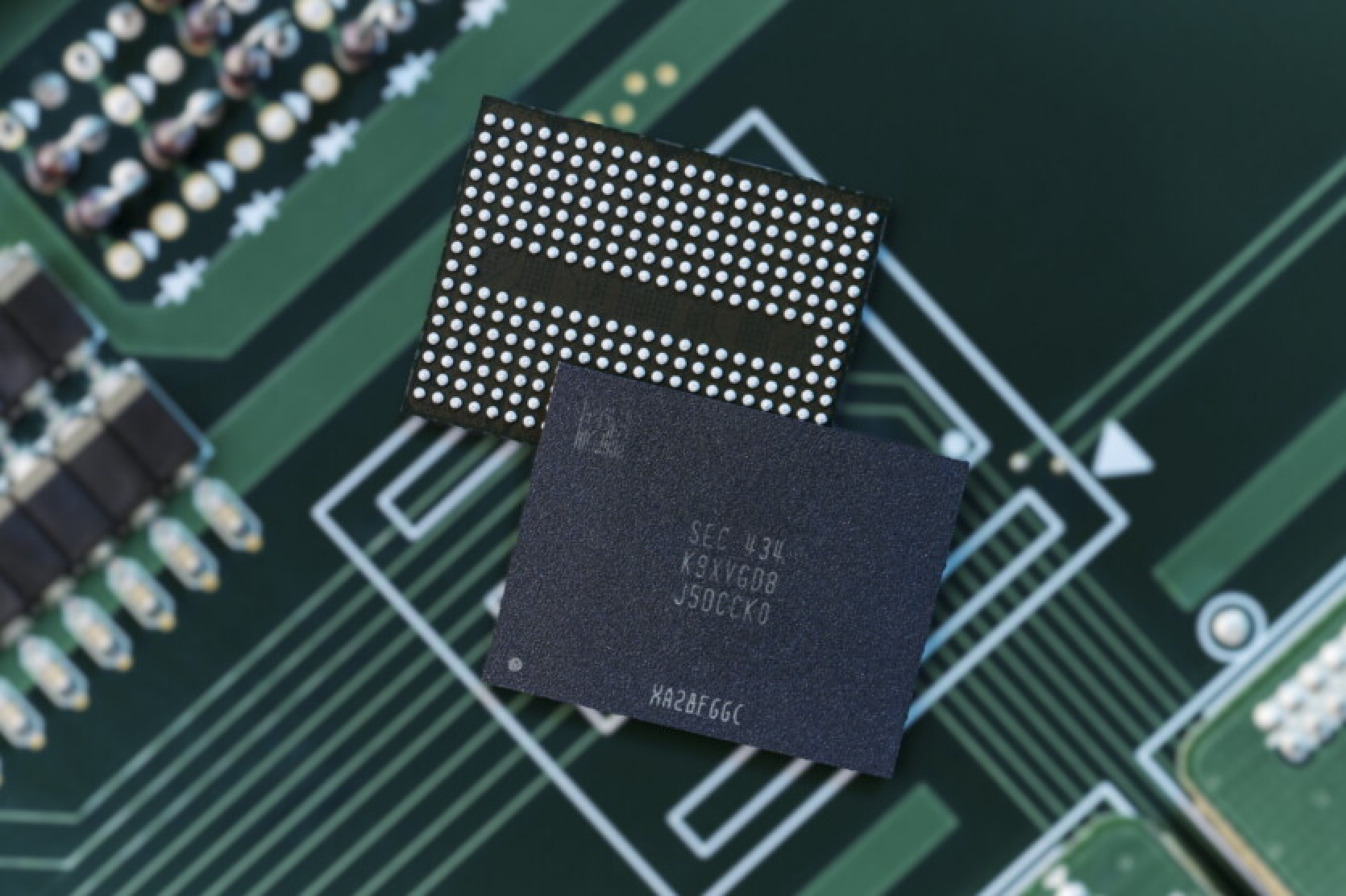

Samsung has commenced mass production of its 9th generation V9 QLC flash memory. This signifies faster, cheaper, and more efficient SSDs.

The company reports that the new V9 QLC leverages the Can Hole Etching technology to achieve the highest number of layers in the industry (280) with a dual-stack design. Building on its previous experience with 9th generation TLC, V9 QLC is approximately 86% denser than the previous generation QLC V-NAND. Samsung is also employing Designed Mold and Predictive Program technologies to enhance data storage performance by around 20% and data input/output speed by 60%.

Power consumption has also been significantly reduced thanks to the Low-Power Design feature, which decreases the voltage managing the NAND cells, resulting in a 30% and 50% reduction in energy consumption for reading and writing data, respectively.

Samsung plans to utilize the 9th generation QLC across various products, ranging from standard solid-state drives to UFS memory for mobile devices. The company promises this new QLC to cloud service provider clients as server SSDs.

The new 280-layer QLC from Samsung appears to be the best in the industry, offering superior density and performance compared to competitors' solutions. The storage density is at 19.5 Gb/mm², making the V9 almost 50% denser than the next best solution, the 232-layer QLC from YMTC at 20.63 mm². Performance is expected to be approximately 33% higher than that of competitors, with a working speed of 3.2 Gb/s.

With these advancements, Samsung is positioned to offer drives that are nearly 50% cheaper. Performance is also set to be significantly improved, as the V9 QLC could operate close to the budget SSDs that utilize TLC NAND flash memory.

Sources: Samsung, Tom's Hardware

Comments (0)

There are no comments for now